Discover Key Benefits of ABC BakerMITS

Understand how our software simplifies the process of production and accounting.

Integrated Production Costing

Accurately track expenses for every batch and product.

Streamlined Manufacturing Workflow

Optimize your bakery’s processes from mixing to packaging.

Comprehensive Accounting Integration

Keep your financials up-to-date with seamless data flow.

Real-Time Inventory Tracking

Monitor stock levels instantly to reduce waste and costs.

Fully Integrated and Automated

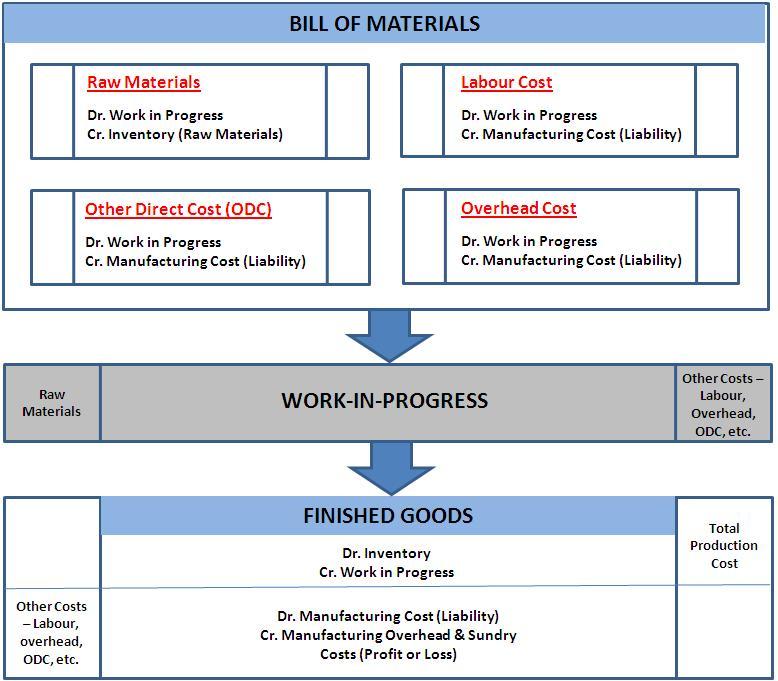

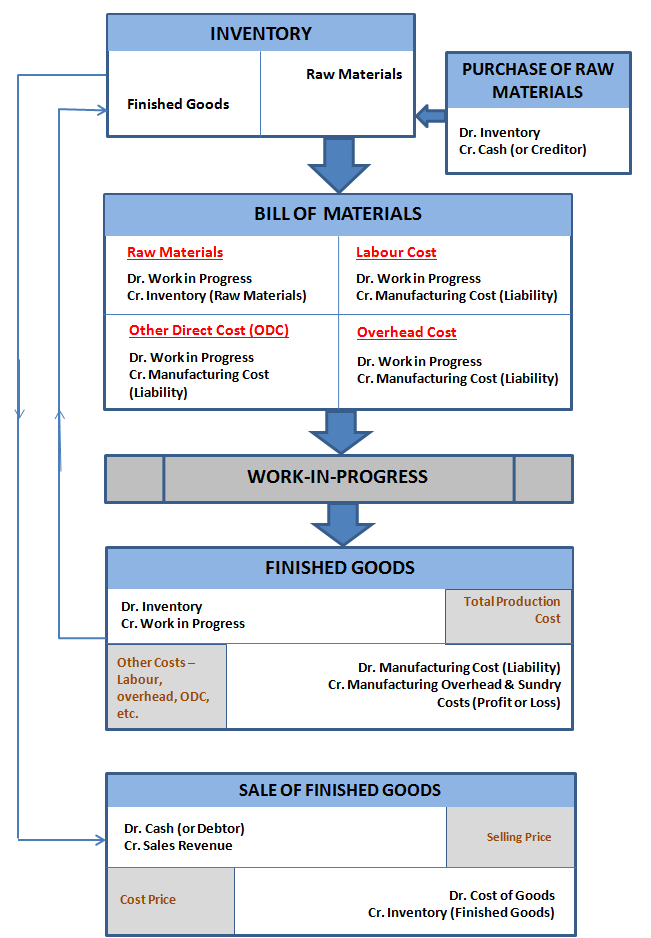

The movement from Raw Materials through Manufacturing to Inventory and Sales is seamless and fully automated.

Basic Introduction to Production Costing and Accounting

You may have heard of the term “Manufacturing Accounting” or “Bill of Materials,” and all the hypes and dread associated with manufacturing accounts. Perhaps, you are one of those who think that automated manufacturing accounting is only meant for large corporations with mega budgets. This is one of the myths about accounting we are out to demystify with our smart software solutions for small and medium businesses.

The first step in manufacturing accounting involves the preparation of the Bill of Materials for each product. The Bill of Materials contains the list of all the items, the unit cost and quantity for each item needed to produce the product or goods. The Bill of Materials is a mandatory requirement, irrespective of what you want to manufacture, the size and the type of company.

Manufacturing accounting involves accounting for the cost of all the materials and resources you employ and deploy in the production of goods (all of which must be included in your Bill of Materials) to enable accurate determination of the cost of the finished products, based on the contribution of each item. The materials and resources to be included in the manufacturing or production Bill of Materials can be classified into the following categories:

- Raw Material

- Labour

- Depreciation from Property, Plant and Equipment

- Other Direct Cost

- Overhead Cost

The Bill of Materials must contain the precise quantity and unit price for each item needed to produce a given quantity of a particular product. Failure to determine these cost components accurately also means failure to determine your profit accurately.

It does not matter whether you are manufacturing on an industrial scale or from your kitchen—the result is the same: If you cannot determine what it costs you to produce a product accurately, you will, certainly, not be in a position to know how much profit or loss you are making until, perhaps, things get out of hands.

We do understand that the process of accurate costing and accounting to produce goods can be too tedious and expensive for Small and Medium Enterprises (SMEs). That is why we have developed a special tool called Bill of Materials Processing and Control (BOMPAC) and offer it as an optional module in our ABC Toolkit financial and business solution for Small and Medium Enterprises (SMEs). This tool is designed to automate and account for all costs associated with the production or manufacturing of any goods, from Bill of Materials through Work In Progress to Inventory. It also allows you to determine your selling price based on a percentage markup.

Apart from the general offering, we have also built a customised production costing and accounting solution, called ABC BakerMITS, for the Bakery.

How ABC BakerMITS Simplifies Your Bread Production Costing and Accounting

Automated Solution for Bakeries

Question: Do you know exactly how much it costs you to produce a loaf of bread?

Before you attempt to answer this question, remember that you will have to consider the following:

- Raw Materials Cost

- Labour Cost

- Other Direct Cost

- Overhead Cost

- Depreciation on Machinery

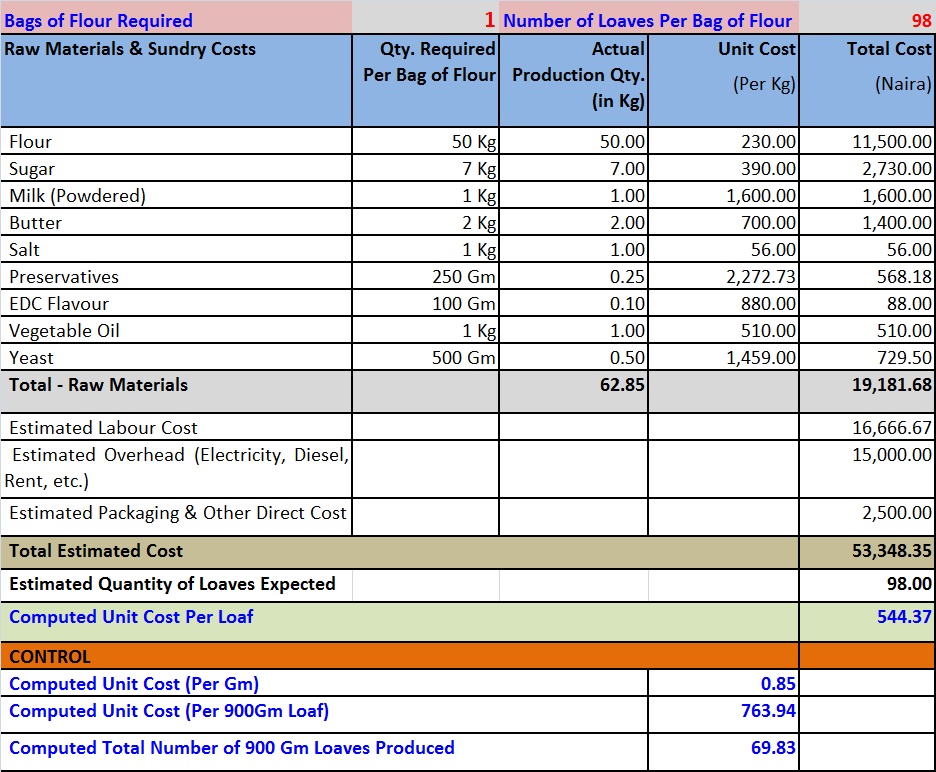

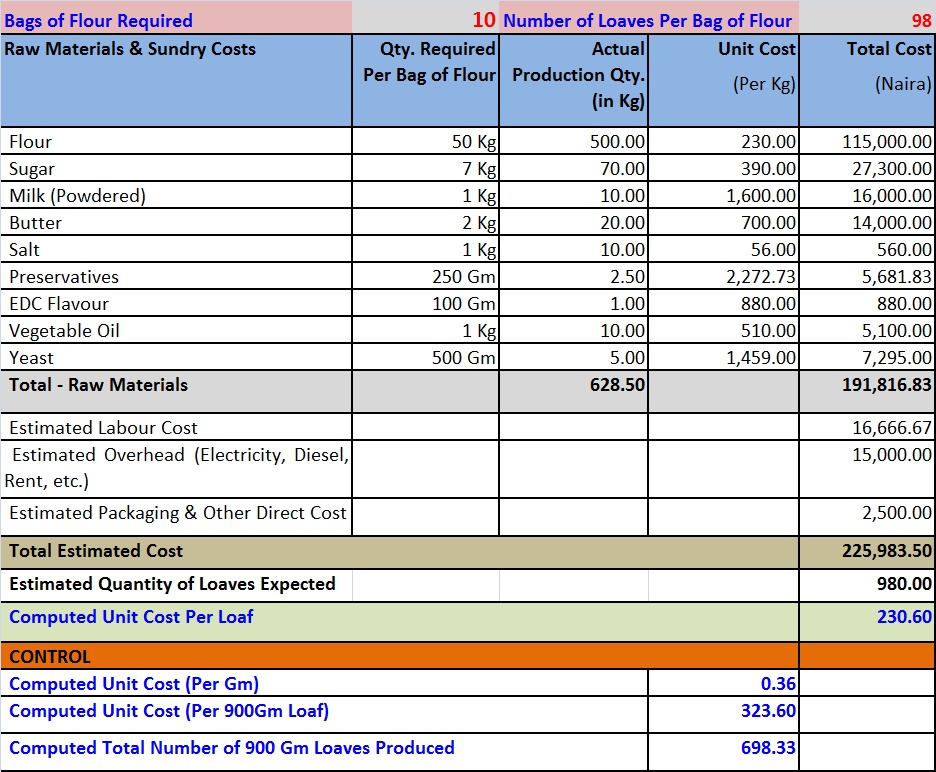

Now, look at the two tables below: The first table shows the computed unit cost for a 900 g loaf of bread with 1 bag of flour (50 Kg), while the second table shows the unit cost of a 900 g loaf of bread with 10 bags of flour. What is the difference?

The difference is clear. However, the truth is that no matter how meticulous you are with your manual processes, your results will be off the mark. Only an automated tool, such as ABC BakerMITs, can provide you with a full and clear picture of the fine details involved in your production costing. These fine details determine the difference between success and failure in an industry where competition is stiff and the profit margin is so low. This is why we decided to create BakerMITS—an automated production costing, accounting, analysis and reporting tool, customised for Bakeries.

Fully Integrated and Automated Solution…

BakerMITS is fully automated to capture all the cost components involved in the production of bread, confectioneries and allied products—from Bill of Materials, through Work in Progress and move the finished goods to Inventory automatically—with all the relevant accounting entries. The only manual intervention required in the whole process is just the click of a mouse. The system allows you to create a reusable template for each of the goods you manufacture.

From Raw Materials Inventory through Production Work -In-Progress to Finished Goods Inventory and Sales, all the relevant accounting entries are made for you automatically; your raw materials and finished goods inventories are automatically updated for every production run and sale.

The chart below depicts the process workflow.

Note that BakerMITS is, first and foremost, accounting software that complies with the International Financial Reporting Standards (IFRS). And that means, apart from production and cost control, you have standard tools to account for your Income & Expense (including sales and purchases), your Fixed Assets, Inventory of Raw Materials and Finished Goods, etc. You also have the full benefits of all standard accounting reports, such as Trial Balance, Balance Sheet, Income Statement, Statement of Account, Sales & Purchases Journals, etc.

How We Can Help You

- We will install and configure BakerMITS on your computers.

- We will set up your Raw Materials and Finished Products inventories, along with other relevant parameters.

- We will design and create a Bill of Materials base template for each product you manufacture.

- We will give you a few hours of training on how to use the system to cost, manufacture, sell and account for your goods, in line with the international best practices.

BakerMITS Editions

BakerMITS is available in Basic, Standard and Professional Editions.

- The Basic Edition comes with automated Bill of Materials Processing and Control, along with standard accounting tools

- The Standard Edition comes with the Fixed Assets management module, in addition

- The Professional Edition comes with integrated Payroll and Timesheet, in addition to all the other features.

The system can also be priced and deployed either as a single-user or client-server multi-user application.

Remember, it does not matter whether you are manufacturing at industrial scale or from your kitchen—the result is the same: If you cannot determine what it costs you to produce a product accurately, you will, certainly, not be in a position to know how much profit or loss you are making until, perhaps, things get out of hands. Now, you have no excuse to let that happen to you.

You can contact us through ANY OF the following PHONE numbers FOR URGENT ENQUIRIES:

09132312209 (Abuja); 0803 402 2629 (Lagos).